FDM vs SLA – Which 3D Printing is Better for You?

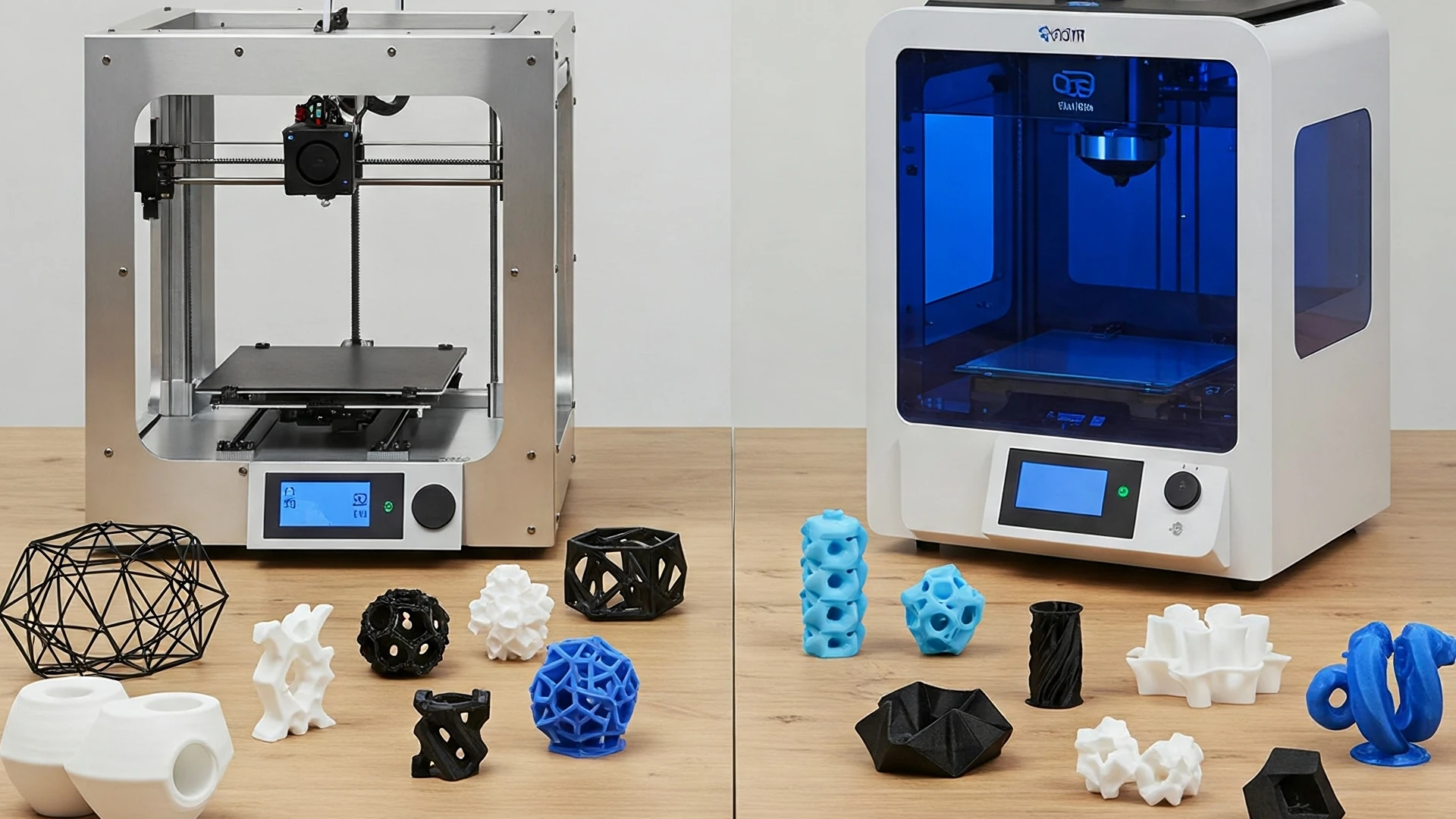

Comparison of the two most common 3D printing technologies

🟠

FDM (Fused Deposition Modeling)

Suitable for:

Functional prototypes and spare parts

Materials:

- PLA (eco-friendly, basic models)

- ABS (durability, mechanical parts)

- PETG (impact resistance)

- TPU (flexible materials)

- ASA (UV resistance, outdoor use)

- Nylon (high strength and durability)

- PAHT-CF (carbon fiber composite, extreme strength)

Advantages:

- Lower price

- Durable prints

- Wide range of materials

- Suitable for larger objects

Disadvantages:

- Visible layers

- Lower detail precision

- Limitations for complex geometries

🔵

SLA (Stereolithography)

Suitable for:

Perfectly smooth and detailed models

Materials:

- Photopolymer resins

- Specialized resins (dental, transparent)

Advantages:

- Highest details

- Smooth surface

- Precision

- Ideal for small objects with details

Disadvantages:

- Lower durability

- Higher price

- Limited print size

- Post-processing required

How to Choose the Right Technology?

Choose FDM if:

- You need functional, mechanically durable parts

- You're looking for a more affordable solution

- You don't need a perfectly smooth surface

- You're printing larger objects

Choose SLA if:

- You need a high level of detail

- You care about a smooth surface

- You're printing small, detailed objects

- You need precise models (e.g., for jewelry)

Not sure? Tell us what you'll be using the print for, and we'll recommend the optimal technology.

Get Advice